The ACI aggregate base testing technician plays a pivotal role in the construction industry, ensuring the quality and safety of structures through rigorous testing and analysis of aggregate materials used in base layers. Their expertise is crucial in safeguarding the integrity and durability of infrastructure projects, from roads and bridges to buildings and dams.

This comprehensive guide delves into the responsibilities, qualifications, testing procedures, equipment, and career opportunities associated with this specialized field, empowering individuals to make informed decisions about pursuing a career as an ACI aggregate base testing technician.

Job Description and Responsibilities

ACI aggregate base testing technicians play a crucial role in the construction industry, ensuring the quality and safety of construction projects by testing and evaluating the properties of aggregate base materials.

Their responsibilities encompass a wide range of tasks, including:

Testing and Evaluation

- Conducting various tests on aggregate base materials, such as gradation, moisture content, density, and strength.

- Analyzing test results to determine the suitability of materials for specific construction applications.

- Providing recommendations on the appropriate use of materials based on test results.

Quality Control and Assurance, Aci aggregate base testing technician

- Monitoring construction processes to ensure compliance with specifications and standards.

- Identifying and addressing any potential quality issues or deviations from specifications.

- Maintaining accurate records of test results and other relevant data.

Reporting and Communication

- Preparing and submitting test reports to clients, contractors, and regulatory agencies.

- Communicating test results and findings to stakeholders in a clear and concise manner.

- Participating in technical meetings and discussions to provide expert advice.

Educational Background and Qualifications

To become an ACI aggregate base testing technician, individuals typically require a high school diploma or equivalent. They should also have a strong understanding of basic mathematics, science, and engineering principles.

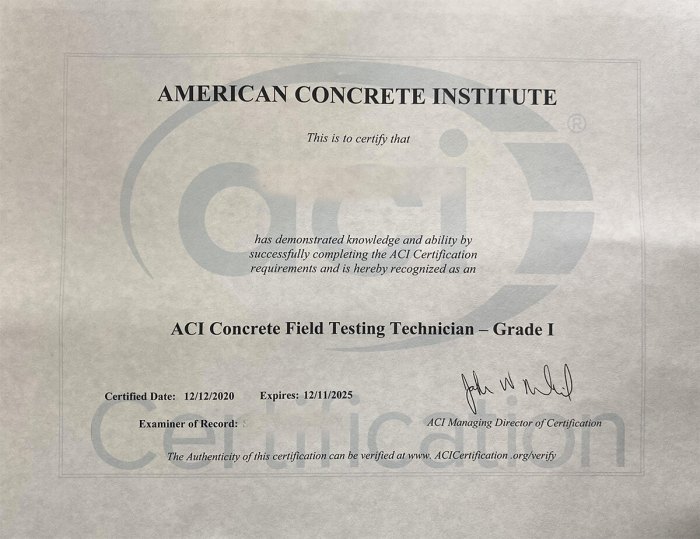

Industry-recognized certifications, such as the ACI Aggregate Base Testing Technician Certification, are highly valued in the field. These certifications demonstrate a technician’s proficiency in performing aggregate base testing procedures and their knowledge of industry standards and best practices.

Ongoing Professional Development

Continuous professional development is essential for ACI aggregate base testing technicians to stay up-to-date with industry advancements and best practices. This can be achieved through attending industry conferences, workshops, and training programs.

Testing Procedures and Standards

ACI aggregate base testing technicians adhere to stringent testing procedures and standards established by the American Concrete Institute (ACI) and other relevant organizations. These procedures ensure the quality and consistency of aggregate materials used in concrete construction.

The testing procedures involve a series of tests designed to evaluate the physical and mechanical properties of aggregates. These tests include moisture content, density, and gradation, each serving a specific purpose in assessing the suitability of aggregates for concrete applications.

Moisture Content

Moisture content testing determines the amount of water present in an aggregate sample. This information is crucial for adjusting concrete mix designs and preventing potential problems such as cracking or reduced strength due to excessive moisture.

Density

Density testing measures the mass of an aggregate sample per unit volume. It provides insights into the compactness and void content of the aggregate, which are important factors in determining the strength and durability of concrete.

Gradation

Gradation testing involves separating an aggregate sample into different size fractions and determining the percentage of each fraction. This information helps ensure that the aggregate has the appropriate particle size distribution for the intended concrete application.

Equipment and Instrumentation

ACI aggregate base testing technicians utilize various specialized equipment and instrumentation to perform accurate and reliable tests on aggregate materials. These tools are essential for assessing the properties and characteristics of aggregates used in road construction and other applications.

Equipment List

- Sieve Shaker:A mechanical device that separates aggregates into different sizes by shaking them through a series of sieves with varying mesh sizes.

- Sieves:A set of screens with specific mesh sizes that allow aggregates to pass through based on their particle size.

- Balance:A precise instrument used to measure the mass of aggregates to determine their specific gravity and other properties.

- Pycnometer:A device used to measure the density of aggregates by determining the volume of water displaced by a known mass of the material.

- Atterberg Limits Device:A set of tools, including a liquid limit device and a plastic limit device, used to determine the moisture content at which an aggregate changes from a liquid to a plastic state.

- Moisture Meter:A device used to measure the moisture content of aggregates by determining the dielectric constant of the material.

- Compaction Mold:A cylindrical mold used to compact aggregates to a specific density for various tests, such as the Proctor compaction test.

- Compaction Hammer:A device used to compact aggregates within the compaction mold by applying a specific amount of energy.

- Los Angeles Abrasion Machine:A rotating drum that contains a sample of aggregates and steel balls, used to determine the resistance of aggregates to abrasion and wear.

- Sand Equivalent Test Kit:A device used to measure the relative amount of clay and silt in aggregates by determining the volume of sand that can be added to a sample without causing the material to become unstable.

Importance of Equipment

The accurate and reliable performance of these tests depends on the proper calibration and maintenance of the equipment and instrumentation. Regular calibration ensures that the equipment is providing precise measurements, while proper maintenance prevents malfunctions and ensures the longevity of the equipment.

By utilizing well-calibrated and maintained equipment, ACI aggregate base testing technicians can ensure the quality and durability of aggregate materials used in various construction projects.

Reporting and Documentation

Accurate and timely reporting of test results is crucial in the field of aggregate base testing. It ensures that the data obtained from testing is reliable, consistent, and can be used to make informed decisions regarding the quality and suitability of aggregate materials for construction purposes.

ACI aggregate base testing technicians generate various types of reports and documentation to communicate test results and findings. These include:

Test Reports

- Provide detailed information on the testing procedures used, test results, and any observations or deviations noted during testing.

- Serve as a record of the testing performed and can be used for quality control, project documentation, and compliance purposes.

Aggregate Base Evaluation Reports

- Summarize the test results and provide an evaluation of the aggregate base material’s suitability for intended use.

- May include recommendations for further testing or actions based on the evaluation findings.

Certification Documents

- Confirm that the aggregate base material meets specified requirements or standards.

- May be required for project approval or to meet regulatory requirements.

Quality Control and Assurance

ACI aggregate base testing technicians play a critical role in ensuring the quality of construction projects by conducting rigorous tests on aggregate materials used in the construction of roads, bridges, and other infrastructure. Their testing contributes to the overall safety and durability of structures by verifying the quality of the materials used and ensuring compliance with industry standards.

The tests performed by ACI aggregate base testing technicians include:

- Gradation analysis to determine the particle size distribution of the aggregate

- Moisture content testing to measure the amount of water present in the aggregate

- Specific gravity and absorption testing to determine the density and water absorption capacity of the aggregate

- Strength testing to assess the load-bearing capacity of the aggregate

- Durability testing to evaluate the resistance of the aggregate to weathering and other environmental factors

The results of these tests are used to determine the suitability of the aggregate for use in construction projects. If the aggregate does not meet the specified requirements, it may be rejected or blended with other materials to improve its properties.

By ensuring the quality of the aggregate used in construction projects, ACI aggregate base testing technicians contribute to the safety and durability of structures, ensuring that they can withstand the demands of everyday use and provide a safe and reliable environment for the public.

Career Advancement and Opportunities

ACI aggregate base testing technicians have ample opportunities for career advancement and specialization. With experience and additional training, they can progress to more senior roles or pursue specialized certifications.

Career advancement paths may include:

Supervisory Roles

- Aggregate Testing Supervisor

- Quality Control Manager

- Materials Testing Laboratory Manager

Specialization

- ACI Aggregate Testing Technician – Concrete

- ACI Aggregate Testing Technician – Asphalt

- ACI Aggregate Testing Technician – Geotechnical

Helpful Answers: Aci Aggregate Base Testing Technician

What is the primary responsibility of an ACI aggregate base testing technician?

To conduct tests on aggregate materials used in base layers to ensure they meet specified standards for moisture content, density, and gradation.

What educational qualifications are required to become an ACI aggregate base testing technician?

Typically, a high school diploma or equivalent, along with industry-recognized certifications such as the ACI Concrete Field Testing Technician – Grade I.

What are the career advancement opportunities for ACI aggregate base testing technicians?

With experience and additional certifications, technicians can advance to supervisory roles, quality control managers, or specialized testing engineers.